Our Oyster Farming Process

Growing farm raised oysters is no easy feat. The process involves many steps and lots of TLC!

1

Spring Seed Arrival and Upwelling

We purchase baby oyster seed from the hatchery each Spring. The seed is only about 1 millimeter in length and is packed in a very fine mesh enclosure. The seed looks like small pepper flakes when it arrives.

We place the seed in solar powered floating upwellers where the tiny oyster babies are in a protected environment. Here they can feed and grow on nutrient rich water. Upwellers provide the ideal environment given that the seed is protected from the wind and waves of the York River and the nutrient rich water allows the oysters to grow quickly. The solar powered pumps push water up and over the oysters in small silos so they constantly receive a fresh supply of phytoplankton. We do not burn any fossil fuel in this upwelling process. The baby oysters remove excess nitrogen and carbon based nutrients from the water thereby improving water quality and clarity. This is actually a nitrogen and carbon negative process. Truly amazing!

2

Grading

Oysters, like any animal, grow at different rates. So we have to separate the fast growers from the slow growers. We do this because the varying sizes of the oysters in the upweller create a compact mass with very little nooks and crannies for water to seep in and flow over the oysters. This compaction slows the rate of growth, so we separate them out to silos with homogenous seed sizes to maximize the rate of water flow.

3

Graduation to the Nursery

Once the oyster seed is large enough, it is moved out of the upwellers and placed in mesh bags contained in floating cages. The cages keep the oysters out of the muck so they can feed in the water column and avoid being smothered by sedimentation. This bag and cage system keeps the crabs and stingrays from eating all our precious oysters. Hog nosed rays have been known to gobble up oyster seed plantings in a single day’s feeding frenzy unless the baby oysters are protected in cages!

4

Summer Sorting and Splitting

We monitor the oysters in our floating cages to determine when they need to be removed for a run in our oyster tumbler. On our Oysterplex we have a specially designed oyster tumbler that grades the oysters according to size, washes the oysters, and chips off the leading edge of the shell to give the oyster that wonderful cuppy appearance over time. Simultaneously we “split” the volume of oysters into roughly double the number of cages, thereby increasing the amount of water flow and decreasing the competition for nutrients within the cage. We repeat this process every 4 weeks throughout the summer and fall.

5

Winter Dormancy

Because of the colder temperatures and lower salinity of the winter water, the oysters slow down their feeding and growth. Eventually they enter a state of dormancy. During winter, we stop the sorting and splitting process and simply monitor the cages to ensure they remain in good condition during nor’easter storms and winter winds.

6

Spring Awakening

Once the water temperatures and salinity begin to increase, the oysters come out of dormancy and begin feeding again. During this time we resume the tumbling, sorting and splitting process while receiving our next “vintage” of oyster seed from the hatchery for the upwellers. Once the oysters reach approximately 2 inches in size they are placed in cages out in the York River on the old original Anderson’s Neck oyster beds where the wave action will toughen up the oysters and strengthen their abductor muscles. This prepares the oysters for shipment where “no wimpy oysters” will be allowed to leave the water.

7

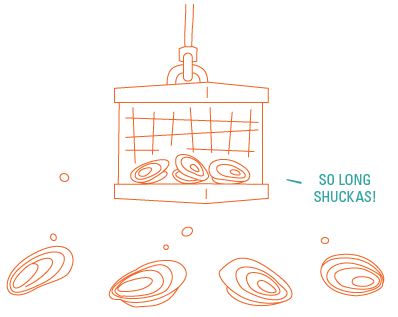

Fall and Winter Harvesting

After approximately 18 months, the oysters are toughened up, and are ready to be harvested. We pull up the cages and pick the “markets” that are ready for sale. We wash down these beautiful market oysters, count them, bag them up, and place them in boxes if they are being shipped direct. We then haul them on our oyster boat to the dock where we run them to the mainland on our oyster cart where trucks are awaiting shipment.

8

Delivery

Our oysters are shipped to restaurants in refrigerated trucks within 24 hours of being taken out of the water. Similarly if they are being shipped direct, they are packed in Styrofoam coolers with frozen gel pack inserts, and placed into non-bleached corrugated boxes where they are shipped overnight to your door.